Buy JCO Pipes at Indosup

JCO Gas Pipe Ltd.

Indosup is the largest procurement partner for JCO Spiral weld pipes.

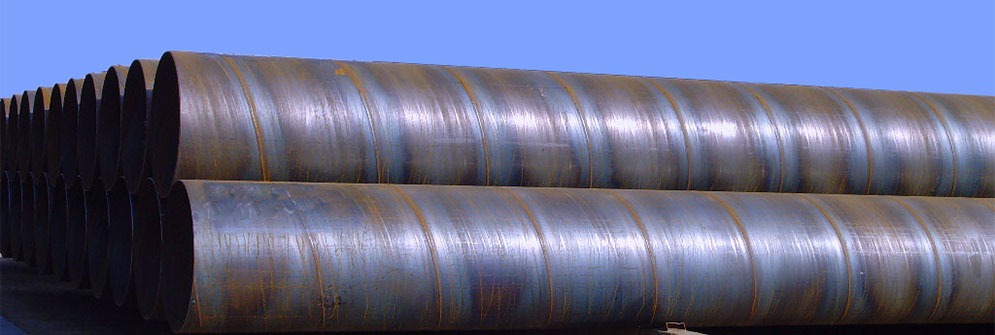

JCO pipes are high-quality, spiral-welded pipes used in various industrial applications. Manufactured through the JCO-E press method, these pipes offer excellent strength, durability, and reliability. Ideal for heavy-duty projects like oil, gas, and water transportation, JCO pipes ensure cost-effective and long-lasting solutions for infrastructure and construction needs.

Email your inquiries to sales@indosup.com

OR

Whatsapp your inquiries to +91 9599610007

Key Stages in JCO Pipe Manufacturing

1. Entry Line

The entry line is where the raw material, typically a steel plate or coil, enters the pipe manufacturing process. It involves:

- Uncoiling or Plate Feeding: Steel is fed into the line from coils or sheets.

- Straightening: The material is straightened and prepared for the subsequent forming steps.

- Edge Milling: The edges of the plate or strip are beveled and prepared for welding.

This stage ensures the material is ready for shaping into a pipe.

2. Forming Stand

The forming stand is where the actual shaping of the pipe occurs, often in multiple stages:

- Initial Bending: The steel plate is gradually bent into a circular or cylindrical shape. In JCO pipes, this includes the J, C, and O-shaped bending process.

- Rollers/Presses: Multiple forming rollers or hydraulic presses progressively shape the material.

- Tack Welding: Temporary welding may be done to maintain the pipe’s shape before final welding.

The forming stand ensures that the steel sheet or plate is transformed into the basic pipe shape before welding.

3. Exit Line

The exit line is the final stage of the manufacturing process after the pipe has been fully formed and welded. It includes:

- Welding: Final continuous seam welding (both internal and external) is completed.

- Sizing & Calibration: The pipe is sized to exact specifications using mechanical or hydrostatic methods.

- Inspection & Testing: The pipe undergoes rigorous quality control checks, including non-destructive testing.

- Cutting: Pipes are cut to the required length.

- Conveying: The finished pipe is conveyed out of the production line for final inspection and storage.

This process ensures the pipes meet the necessary specifications and quality standards for use in construction and industrial applications.

Indosup follows a strategic and comprehensive approach to procure JCO pipes from reliable manufacturers and suppliers across India. With a focus on quality, the company collaborates with some of the most reputed steel mills and pipe manufacturers to ensure they meet industry standards and project specifications. Indosup sources JCO pipes in bulk, ensuring availability in various sizes and grades to meet the specific demands of different industries, including construction, oil and gas, and water transportation.

The procurement process starts with identifying suppliers that have a proven track record in producing high-quality, spiral-welded JCO pipes. Indosup ensures that the pipes undergo rigorous quality control measures, including material testing, weld inspections, and dimensional checks. By working closely with manufacturers, Indosup ensures all products meet the strict standards required for critical infrastructure projects.

Once sourced, the JCO pipes are transported efficiently through Indosup’s vast supply chain network, which spans across India. This enables timely delivery to various project locations, ensuring that construction timelines are met without delays. Whether it’s for large-scale infrastructure or smaller industrial applications, Indosup’s robust procurement system ensures the availability of reliable and durable JCO pipes for clients nationwide.

Key Applications of JCO Spiral Saw Pipes in Various Industries

JCO spiral saw pipes are widely used across various industries due to their strength, durability, and cost-effectiveness. Key applications include:

Oil & Gas Pipelines: These pipes are ideal for transporting oil, natural gas, and other hydrocarbons over long distances due to their ability to withstand high pressure and harsh environments.

Water Transmission: JCO pipes are used for large-scale water distribution systems, including irrigation and urban water supply pipelines.

Construction & Infrastructure: Their robust structure makes them suitable for piling, foundation work, and structural supports in bridges, highways, and buildings.

Sewage & Drainage Systems: JCO spiral pipes are commonly used in waste and stormwater management systems due to their corrosion resistance.

Marine Applications: These pipes are used in offshore platforms, underwater pipelines, and coastal construction, as they offer excellent resistance to corrosion and environmental stress.

Hydroelectric Projects: They are employed in penstocks and other water conveyance systems in hydroelectric power plants.

Overall, JCO spiral saw pipes provide a reliable, long-lasting solution for heavy-duty applications in industries where high performance and durability are essential.

PRODUCTS: PIPE COATING SOLUTIONS

Liquid Epoxy Coating: This two-part epoxy coating is applied to the internal surface of pipes, creating a tough, protective layer with impressive hardness. Applied as per IS-3589, AWWA-C-210 standards using airless spray techniques.

Key Benefits:

- Superior adhesion to mild steel

- Resistant to water, alcohol, solvents, and chemicals

- High mechanical strength and excellent abrasion resistance

Cement-Mortar Lining: Primarily used for water distribution pipes, this lining is applied to the inside of the pipe. The coating is done according to IS-3589, AWWA-C-205 & C-602 standards or customized specifications. The mortar is centrifugally applied to pipes with diameters ranging from 20 to 64 inches and lengths of 6 to 12.2 meters using cutting-edge equipment.

Key Benefits:

- Highly resistant to alkaline conditions

- Effectively prevents corrosion, extending pipe life

- Provides strong abrasion resistance

Guniting (External Cement Lining): Known as external cement lining, this technique is widely used for water and sewage pipes. Applied according to IS-3589, AWWA-C-205 & C-602 standards or customized mixes, the coating is reinforced with a welded wire mesh for added durability.

Key Benefits:

- Excellent compatibility with alkaline environments

- Strong corrosion protection, extending pipe longevity

Coal Tar Tape Coating: Applied as per IS-3589, IS-15337, and AWWA-C-203 standards, this process involves sandblasting the pipe (ISO-8501), applying a primer, and wrapping coal tar tape with heat. The tape is composed of glass fiber and coal tar.

Key Benefits:

- Excellent resistance to heat and water

- Protection against cathodic disbondment

Epoxy-Based Paint (Internal/External): Epoxy zinc-rich primers are used to provide superior protection in highly corrosive environments. The zinc delivers cathodic protection, and the pipes can be top-coated with epoxy, polyurethane, or enamel paints for specific needs. Applied using airless spray techniques.

Key Benefits:

- Exceptional adhesion to prepared steel

- Excellent corrosion resistance

- High resistance to abrasion

External Varnish: This varnish forms a protective film on the surface of steel pipes, providing a hard, non-oily coating after curing, which helps protect pipes during storage.

Key Benefits:

- Protects steel pipes during extended storage periods

- Forms a durable, non-greasy protective layer

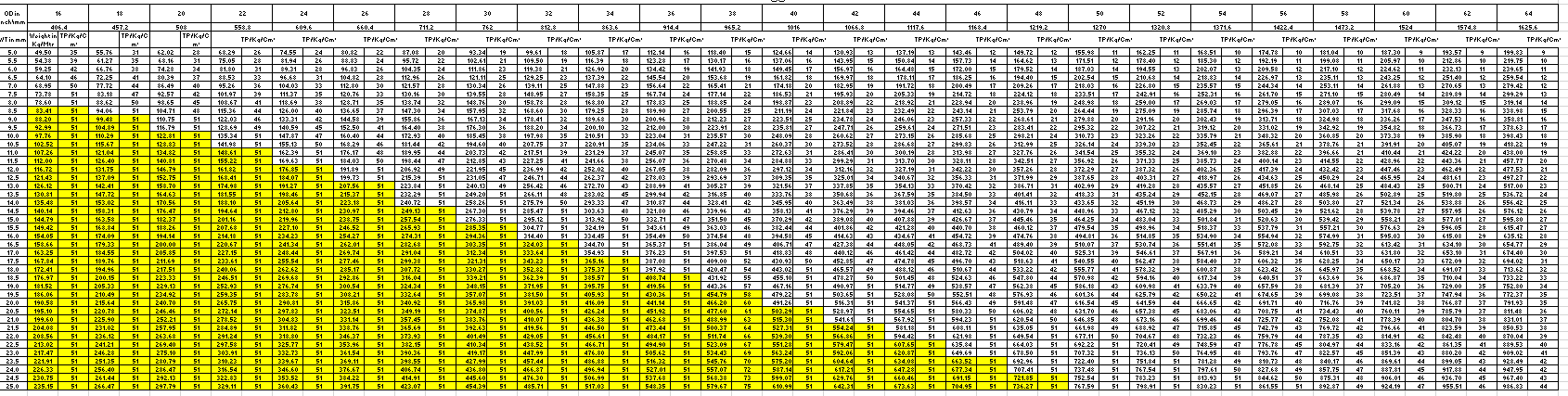

Weight in Kilograms per Running Meter & Corresponding Test Pressure

Understanding JCO Gas Pipes: A Reliable Solution for Natural Gas Transportation

JCO gas pipes are a specialized type of pipe designed for the efficient and safe transportation of natural gas and other gaseous materials. The name “JCO” comes from the unique method used in their manufacturing process, where steel plates are progressively formed into the shape of “J,” “C,” and then “O,” followed by welding. This innovative approach results in pipes that are not only strong and durable but also tailored for high-pressure applications, making them ideal for gas distribution networks.

What Sets JCO Gas Pipes Apart?

One of the standout features of JCO gas pipes is their ability to withstand extreme pressures and harsh environmental conditions. Made from high-quality steel, these pipes exhibit excellent mechanical properties, ensuring they can handle the demands of gas transmission without compromising safety. Additionally, JCO pipes are highly resistant to corrosion, which is critical for maintaining the integrity of gas lines over time.

The Role of Indosup in Procuring JCO Gas Pipes

Indosup, located in India, plays a vital role in the procurement of JCO gas pipes across the country. With a strong commitment to quality and customer satisfaction, Indosup collaborates with trusted manufacturers to source these high-performance pipes. The company focuses on building relationships with reputable suppliers who adhere to stringent industry standards. This ensures that every JCO gas pipe procured by Indosup meets the necessary specifications for safety and performance.

Indosup understands the critical importance of reliable gas transportation systems for both residential and industrial applications. By offering a wide range of JCO gas pipes in various sizes and specifications, Indosup ensures that its clients have access to the right products for their specific needs. The company’s dedicated procurement team actively engages with manufacturers to stay updated on the latest advancements in pipe technology and material quality.

Trust and Reliability

When it comes to sourcing JCO gas pipes, trust is paramount. Indosup has established itself as a reliable player in the construction material procurement sector by prioritizing quality and transparency. The company conducts thorough inspections and quality checks on every batch of JCO pipes before they reach the clients. This rigorous quality assurance process helps build confidence among customers, knowing they are receiving top-tier products.

Indosup also emphasizes timely delivery, ensuring that clients can proceed with their projects without unnecessary delays. The company’s extensive logistics network facilitates the smooth transportation of JCO gas pipes to various locations throughout India, making it a convenient option for businesses seeking reliable procurement solutions.

Conclusion

In summary, JCO gas pipes are a vital component for the safe and efficient transportation of natural gas. Their unique manufacturing process, combined with exceptional strength and corrosion resistance, makes them an ideal choice for various applications. Indosup, located in India, is committed to providing high-quality JCO gas pipes, ensuring that clients have access to reliable solutions for their gas transmission needs. With a focus on quality, trust, and timely delivery, Indosup stands out as a key player in the procurement of JCO gas pipes across India. Whether for residential, commercial, or industrial use, choosing JCO gas pipes through Indosup guarantees a dependable solution for gas transportation.

Discover a Wide Range of Pipes at Indosup: Your One-Stop Shop for All Pipe Solutions

Email your inquiries to sales@indosup.com

OR

Whatsapp your inquiries to +91 9599610007