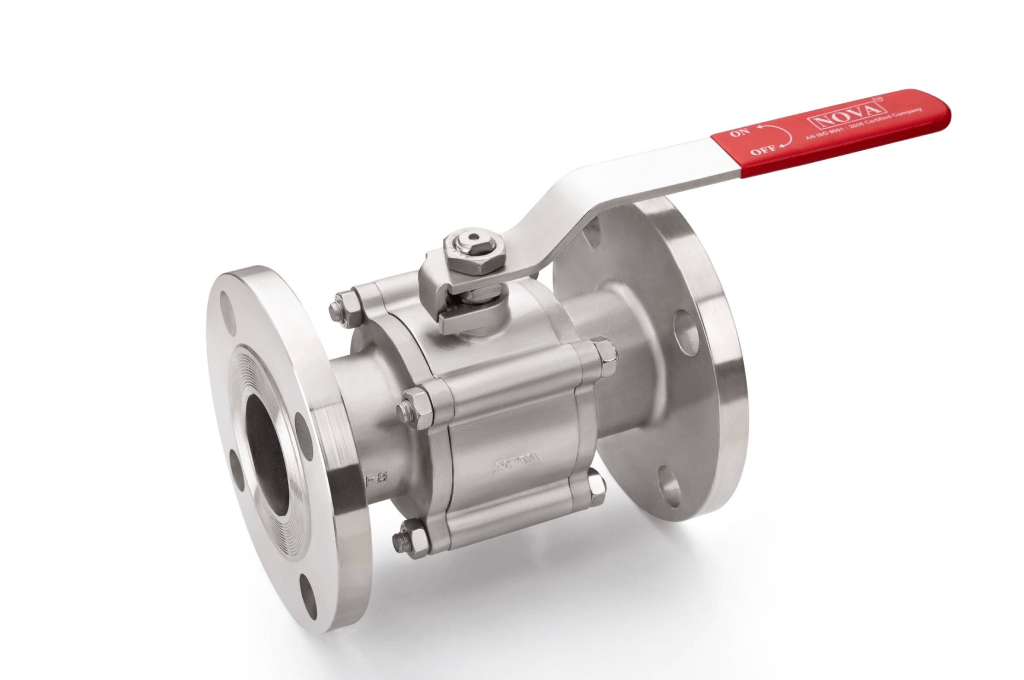

BALL VALVE

Brands

- ZOLOTO

- SANT

- KARTAR

- SKS

- AUDCO

- ADVANCE

- LEADER

- & Many More

The ball valve is a popular type of quarter-turn valve that uses a spherical disc (the ball) to control flow. When the handle or lever is turned 90 degrees, the ball rotates to either allow or block fluid flow. Ball valves are known for their quick and efficient operation, making them ideal for applications that require rapid flow control.

Characteristics of Ball Valve:

Quick Operation: The quarter-turn operation of ball valves allows for rapid opening and closing, minimizing flow resistance and pressure drop.

Leakage Prevention: Ball valves provide excellent sealing capabilities, reducing the risk of leakage in the closed position.

Versatility: Ball valves are available in various materials and configurations, suitable for a wide range of applications and fluid types.

Applications of Ball Valve:

Residential Plumbing: Ball valves are commonly used in household plumbing systems for shut-off and control of water flow.

Industrial Processes: Ball valves find applications in industrial processes, including petrochemical, pharmaceutical, and water treatment industries.

Natural Gas and Oil Pipelines: Ball valves are utilized in the energy sector for flow control in natural gas and oil pipelines.

Types of Ball Valves: Floating, Trunnion, and More

Ball valves come in various types, each designed for specific applications and operating conditions. Understanding the differences between floating ball valves, trunnion ball valves, and other variants is essential for making informed procurement decisions.

Factors to Consider Before Procurement: Pressure, Temperature, and Material Selection

Before procuring ball valves, it’s crucial to assess factors such as operating pressure and temperature, material compatibility, and end connection type. These considerations ensure that the selected valves meet the requirements of the intended application and environment.

Choosing the Right Supplier: Reputation, Quality Assurance, and Technical Support

Selecting a reputable and reliable supplier is paramount in securing high-quality ball valves. Factors such as supplier reputation, quality assurance practices, and technical support capabilities should be carefully evaluated to ensure a successful procurement process.

Procurement Process Step by Step: Needs Assessment to Delivery and Logistics

The procurement process for ball valves involves several key steps, including needs assessment, supplier research, quotation evaluation, negotiation, order placement, quality inspection, and delivery management. Each step requires careful planning and execution to ensure timely and cost-effective procurement.

Ensuring Quality Control and Compliance: Inspection, Testing, and Certification

Quality control and compliance are essential aspects of ball valve procurement. Inspecting materials, verifying dimensional accuracy, and ensuring compliance with industry standards and regulations are critical steps in guaranteeing the reliability and performance of procured ball valves.

Mitigating Risks in Procurement: Supplier Evaluation and Contractual Terms

To mitigate risks associated with ball valve procurement, thorough supplier evaluation, and clear contractual terms are essential. By establishing robust supplier relationships and defining contractual obligations, organizations can minimize the potential for supply chain disruptions and quality issues.

Leveraging Technology in Procurement: Online Platforms and Supply Chain Management Tools

The digitalization of procurement processes offers significant benefits in terms of efficiency and transparency. Leveraging online procurement platforms, digital catalogs, and supply chain management tools can streamline the procurement of ball valves and enhance overall operational efficiency.

Best Practices for Successful Procurement: Clear Objectives and Continuous Improvement

Adopting best practices such as defining clear procurement objectives, conducting market research, building strong supplier relationships, and investing in continuous improvement initiatives are key to successful ball valve procurement. These practices ensure that organizations can optimize their procurement processes and achieve their operational goals.

Conclusion: Optimizing BALL VALVE Procurement for Operational Excellence

In conclusion, effective ball valve procurement is essential for maintaining operational excellence in industrial settings. By understanding the types of ball valves, considering key factors before procurement, choosing the right suppliers, and following best practices throughout the procurement process, organizations can ensure reliable fluid control and system performance.