Buy Surya Roshni steel Pipes at Indosup

Surya Roshni pipes are known for their exceptional quality and durability, making them a trusted choice for various industrial, construction, and infrastructure projects. Manufactured using advanced technology, these pipes offer superior strength, corrosion resistance, and longevity.

Available in a range of sizes and specifications, Surya Roshni pipes cater to diverse applications such as water supply, gas distribution, and structural purposes. With stringent quality control and adherence to industry standards, Surya Roshni ensures reliable performance, making their pipes a top choice for professionals seeking dependable piping solutions in critical applications.

Email your inquiries to sales@indosup.com

OR

Whatsapp your inquiries to +91 9599610007

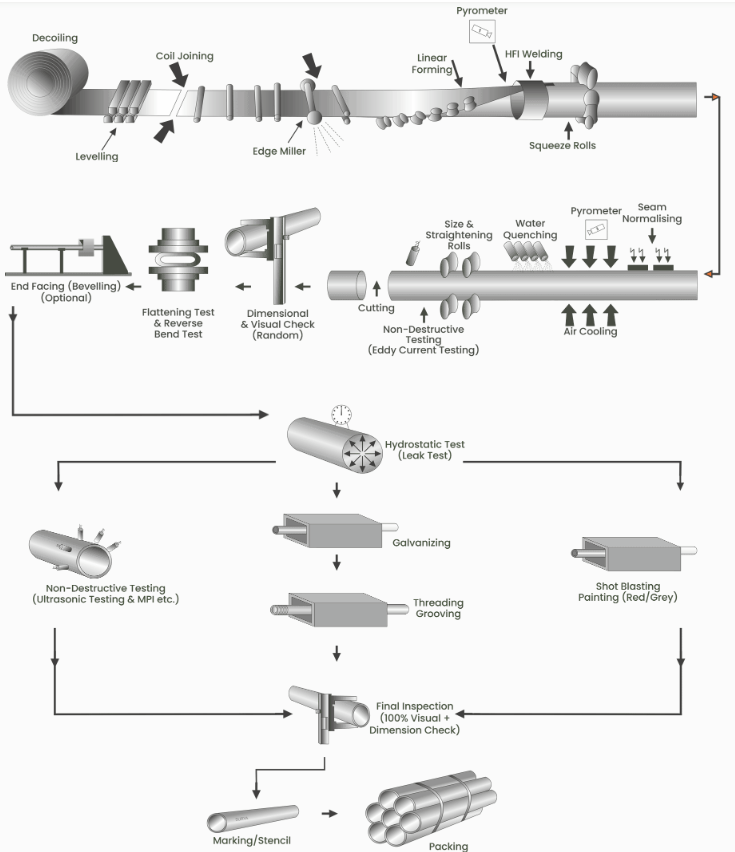

The manufacturing process of Surya Steel Pipes is based on cutting-edge technology and strict quality control.

Surya Roshni uses high-quality raw materials, including steel coils and billets, ensuring that every pipe meets stringent industry standards. The company employs advanced machinery to shape, weld, and finish the pipes, making them suitable for various applications.

The pipes are manufactured using different processes such as Electric Resistance Welding (ERW) and Seamless Pipe Manufacturing, depending on the type and size of the pipe.

ERW pipes are widely used for lower-pressure applications, while seamless pipes are preferred for high-pressure and critical operations like oil and gas transportation.

What are ERW PIpes & Structural Steel Hollow Sections?

ERW (Electric Resistance Welded) pipes are steel pipes produced through a process that involves welding the edges of steel plates or strips using electric resistance. The process does not require any filler material; instead, heat generated by the electric current melts and joins the edges together. ERW pipes are known for their precision, uniformity, and cost-effectiveness, making them a popular choice in many industries.

ERW Pipe Manufacturing Process:

- Raw Material: Steel sheets or strips are rolled into a cylindrical shape.

- Welding: The edges are welded using electrical resistance, creating a strong seam.

- Sizing and Shaping: The pipe is passed through rollers to achieve the correct diameter and wall thickness.

- Cutting and Finishing: Pipes are cut to required lengths and undergo testing for quality control.

Applications of ERW Pipes:

- Oil and Gas Pipelines: Used for transporting petroleum, gas, and other liquids.

- Water Supply and Distribution: Popular in water pipelines for municipal and industrial use.

- Construction: Often used for structural applications like scaffolding, columns, and fencing.

- Automotive and Machinery: Utilized in the manufacturing of components due to their strength and consistency.

Key Benefits:

- Cost-Effective: ERW pipes are cheaper to manufacture compared to seamless pipes.

- Uniformity: High precision in diameter and wall thickness.

- Strength: Strong welds capable of handling high pressures and loads.

What are Structural Steel Hollow Sections?

Structural Steel Hollow Sections are steel tubes with a hollow cross-section, usually in shapes such as circular, rectangular, or square. These sections are widely used in structural and mechanical applications where strength, lightness, and versatility are required. Hollow sections are manufactured using either cold-forming or hot-forming processes, and their hollow structure makes them lightweight while maintaining high strength.

Types of Hollow Sections:

- Circular Hollow Sections (CHS): Tubular pipes with a round cross-section, ideal for columns, pipelines, and aesthetic designs.

- Rectangular Hollow Sections (RHS): Widely used in structural applications due to their ability to resist bending and torsional loads.

- Square Hollow Sections (SHS): Commonly used in frameworks and load-bearing structures because of their uniformity and strength.

Manufacturing Process of Hollow Sections:

- Forming: Steel strips or plates are rolled into the desired shape, whether circular, rectangular, or square.

- Welding: The edges are welded using an electric resistance process, similar to ERW.

- Sizing: The sections are sized to the desired dimensions using rolling mills.

- Quality Control: Hollow sections undergo testing for structural integrity and load-bearing capacity.

Applications of Hollow Sections:

- Building Structures: Used in the construction of frameworks, columns, and beams due to their high load-bearing capabilities.

- Bridges and Towers: Structural hollow sections are essential in designing towers, bridges, and large infrastructure projects due to their light weight and strength.

- Automotive and Machinery: Used in car frames, machinery structures, and other mechanical components.

- Architectural Design: Popular in architectural projects for both aesthetic and structural reasons.

Key Benefits:

- High Strength-to-Weight Ratio: The hollow design offers strength while keeping the structure light.

- Versatility: Available in various shapes and sizes for different structural needs.

- Corrosion Resistance: When coated, these sections resist corrosion, making them durable for outdoor applications.

- Aesthetic Appeal: The clean, simple design of hollow sections is often favored for visible structural elements.

ERW Pipes vs. Structural Steel Hollow Sections

ERW Pipes are mainly circular and used for the transport of liquids, gases, and for structural purposes. They are typically round, but square and rectangular shapes are also available.

Structural Steel Hollow Sections can be circular, square, or rectangular and are primarily used in construction and structural frameworks. Their hollow shape allows for reduced weight without sacrificing strength.

Both ERW pipes and hollow sections are essential in various industries, offering strength, durability, and versatility for different structural and mechanical applications.

Manufacturing Process of ERW Pipes

Spiral Welded Pipes

Spiral welded pipes, manufactured by Surya Roshni, are known for their exceptional strength, durability, and reliability. These pipes are produced through a spiral welding process, where a steel coil is continuously rolled and welded into a spiral seam, creating a cylindrical pipe. The process allows for the production of large-diameter pipes with enhanced structural integrity, making them suitable for high-pressure applications and critical infrastructures.

Surya Roshni is a leading manufacturer of steel pipes in India, and their spiral welded pipes are widely used in industries such as oil and gas, water distribution, and construction. Known for their precision, quality, and adherence to international standards, Surya Roshni’s spiral welded pipes offer a reliable solution for a wide range of applications.

Manufacturing Process of Spiral Welded Pipes

The spiral welded pipe manufacturing process involves the following steps:

Steel Coil Preparation: High-quality steel coils are used as the raw material. The coils are first inspected for any defects to ensure the final product meets quality standards.

Forming: The steel coil is unrolled and fed into a spiral forming machine. The machine shapes the steel into a continuous spiral, forming a cylindrical pipe.

Welding: As the steel is formed into a spiral, the edges are welded together using an automatic submerged arc welding (SAW) process. This ensures a strong, seamless weld with excellent mechanical properties.

Cutting and Finishing: The continuous pipe is cut into desired lengths and subjected to further finishing processes, such as beveling the edges or coating the pipe for added protection.

Testing and Quality Control: Every pipe undergoes rigorous testing, including ultrasonic and hydrostatic tests, to ensure there are no defects in the weld or material. This guarantees the pipe’s ability to withstand high pressure and harsh environments.

Key Features of Surya Roshni Spiral Welded Pipes

Large Diameter Capabilities: The spiral welding process allows for the production of pipes with large diameters, making them ideal for infrastructure projects like water transmission and oil pipelines.

Strength and Durability: Surya Roshni’s spiral welded pipes are designed to withstand high pressures and stresses, making them perfect for demanding applications.

Cost-Effective: Compared to other pipe manufacturing processes, spiral welding is more efficient for producing large-diameter pipes, which helps in reducing costs.

Corrosion Resistance: When coated with anti-corrosion materials, such as epoxy or cement-mortar lining, these pipes offer enhanced protection against environmental factors and corrosion, increasing their lifespan.

Applications of Spiral Welded Pipes

Surya Roshni’s spiral welded pipes are widely used in several key industries due to their versatile nature:

Oil and Gas Transportation: These pipes are commonly used in long-distance pipelines for transporting oil, natural gas, and other fuels. Their ability to handle high pressure makes them suitable for these applications.

Water Transmission: Spiral welded pipes are used in water distribution networks, especially for transporting water over long distances in large volumes. Their strength and large diameters are crucial for this application.

Sewage and Wastewater Systems: These pipes are often used in large-scale drainage and sewage systems due to their corrosion resistance and structural integrity.

Infrastructure and Construction: In the construction industry, spiral welded pipes are used for piling and other structural applications that require strong, load-bearing pipes.

Surya Roshni: Commitment to Quality

Surya Roshni is a leading manufacturer of steel pipes, offering a wide range of solutions for various industries. The company’s spiral welded pipes adhere to international standards, including API 5L for oil and gas pipelines, IS standards for water and sewage pipelines, and more. Surya Roshni ensures that every pipe is subjected to rigorous quality control processes, making them a trusted choice for projects requiring reliability and durability.

Indosup’s Role in the Procurement Process

Indosup is more than just a supplier; it is a partner in your success. Here’s how Indosup ensures a smooth and efficient procurement process for Surya pipes:

Wide Network and Strong Relationships: Indosup has a well-established network of suppliers and manufacturers across India. Its close partnership with Surya Roshni allows Indosup to offer a seamless procurement experience, ensuring you get the right pipes for your project on time. By leveraging its relationships and expertise, Indosup helps clients access the best pricing and delivery terms for Surya pipes.

Comprehensive Product Knowledge: With years of experience in the procurement industry, Indosup has in-depth knowledge of Surya Roshni’s product range. Whether you need ERW pipes for structural applications or spiral welded pipes for oil and gas pipelines, Indosup provides expert advice to help you select the most suitable pipes based on your project’s specific requirements. The team at Indosup is well-versed in the technical specifications of various pipes, ensuring that every order meets the necessary industry standards.

Customized Solutions: Every project has unique needs, and Indosup excels in offering tailor-made procurement solutions. From specifying pipe dimensions to advising on coatings for corrosion resistance, Indosup provides personalized service to match the precise needs of each client. This flexibility ensures that businesses get exactly what they need to keep their projects on track.

Efficient Supply Chain Management: Indosup’s supply chain management is optimized to handle bulk orders and deliver products across India promptly. By streamlining logistics and warehousing, Indosup minimizes delays and ensures that your Surya pipes arrive at your site, ready to use. Whether your project is in a metro city or a remote area, Indosup’s network ensures smooth delivery.

Quality Assurance and Compliance: When procuring from Indosup, clients can be assured of product quality. Surya Roshni pipes go through stringent quality control processes and adhere to both national and international standards, such as IS, ASTM, and API specifications. Indosup takes responsibility for ensuring that all products procured meet these standards and are fully compliant with project requirements.

Benefits of Partnering with Indosup for Surya Pipes

Cost-Effective Procurement: By leveraging its extensive network and relationships with manufacturers, Indosup offers competitive pricing for Surya Roshni pipes. This helps businesses keep their procurement costs under control without compromising on quality.

Technical Expertise: Indosup’s team has technical expertise in understanding the various applications of Surya pipes. This knowledge enables them to provide valuable advice and ensure that the right product is chosen for your project.

Timely Delivery: Indosup’s robust logistics and supply chain management ensure timely delivery of pipes, even for large-scale projects. The company coordinates every aspect of the procurement process, ensuring that there are no delays in your project timeline.

Reliable Service: With a customer-first approach, Indosup focuses on building long-term relationships with its clients by offering reliable, transparent, and efficient procurement services. This ensures that businesses can depend on Indosup for all their future piping needs.

Explore Other Pipe Solutions with Indosup

In addition to Surya Roshni pipes, Indosup procures a wide variety of pipes and materials from other leading manufacturers. From Jindal pipes to Maharashtra seamless pipes, Indosup provides solutions for all your construction and infrastructure needs. With expertise in handling ERW, GI, MS, and spiral welded pipes, Indosup can support projects of any size or complexity, ensuring that you get the best materials at the best price.

Email your inquiries to sales@indosup.com

OR

Whatsapp your inquiries to +91 9599610007